Apollo ERP is a set of inter-connected modules all designed to work seamlessly and efficiently in providing the crucial data that your organization needs in order to operate a successful manufacturing business. Take a tour of just a few key modules that Apollo ERP offers:

Apollo Master Data Module

At the heart of the Apollo ERP Platform is the Apollo Master Data Module in which all critical information is gathered and stored as a singular source of real time information for use throughout your organization. Detailed information about your clients, suppliers, materials used in production, products, staff, equipment, resources and work cycles is stored in order to be leveraged within the transactional areas of Apollo ERP in order to produce extremely accurate production planning as well as tightly controlled materials management and purchasing controls

Work Cycles

- Various times (machine time, personal time, set-up time, batch-time, change over times etc.)

- Machine capacity using shifts, hours and percentages

- Tools

- Nested bill of materials for machines and tools

Items / Materials

- Dynamic text search (no matchcode-bound)

- Unlimited space for item description

- Multi-language

- Multi-units

- Versions

- Calculation

- Batch Control

- Multi-Client

- Nested Bill of Materials

- 300+ data fields available for defining items & materials

Customer Data

- Unlimited number of invoice addresses per customer

- Unlimited number of delivery addresses per customer

- Multi-currency

- Multi-language

- Complete historical data

- Flexible delivery and payment terms

Bill of Materials

- Endless number of entries

- Endless nesting of materials and resources within BOM

- Contains materials, machines, work cycles, tools

- Using conditional elements for versions and variations

- Time dependent elements

- Material quantities

- Machine times

- Makes reservations for materials as well as resources

- Complete history of BOM for each item

- Endless number of BOMs per item

Apollo Sales Force Automation Module

Through a series of core utilities designed to automate the input and access of key pieces of information, your sales staff and management team will be able to answer critical questions surrounding activity planning and performance evaluation.

Apollo Sales Force Automation (SFA) is a key piece of the Apollo ERP Platform as it is often the initiation point of much of the activity within most businesses. Orders created within Apollo SFA will trigger a wave of updates and recommendations throughout the rest of the Apollo ERP modules. This provides everyone involved in the production of goods throughout your organization with up to date and extremely precise instructions as well as feedback loops to inform the sales staff and management of the status of all orders.

Apollo SFA is also a part of the more comprehensive Apollo CRM Module in which the manipulation and analysis of customer data takes on a more central role.

Order Management

- Unlimited number of items per order

- Blanket orders

- Call-Off orders

- Multi-lingual

- Multi-currency

- Complex pricing and discount module

- Endless record of transactions

- Different order types

- Free text search(customers, items)

- Item availability (current and future)

- Direct connection to Apollo Production module

- Integrated mail and workflow system

- Complex text management

- Variable unit conversion

- Consignment orders

- Unlimited number of customer item numbers and descriptions

- On-the-fly creation of customer and items

Cost Estimation

- Multi-lingual support

- Multi-currency

- Complex text and design options

- Integrated into the Apollo workflow and mail system

- Direct access to customer data, item data and complete history

Apollo CRM Module

Customer Relationship Management is critical to every business, and the manufacturing sector is no different. Apollo CRM has a broad range of features covering such basics as managing core customer data as well as all the relevant quotation and order interactions throughout your entire history with each client. Apollo CRM has the ability to get as complicated as you need it to, packing in an enormous range of features including the ability to provide you with complex pricing and discount models, powerful multi-currency management, connectivity between orders and related production overviews, multi-lingual support for different customers as well as a range of Sales Force Automation tools. These SFA features provide your sales organization a better understanding of their customer base and assists them in creating better planning around core activities as well as providing management with reporting on critical sales metrics.

Features:

- Contact management system

- Sales team management

- Sales funnel management

- Calendar

- Activity reporting

- Sales call and visit recommendations

- Sales activity guide

- Customer profile

- Commission calculation

- Connectivity with Outlook (email, calendar, contacts)

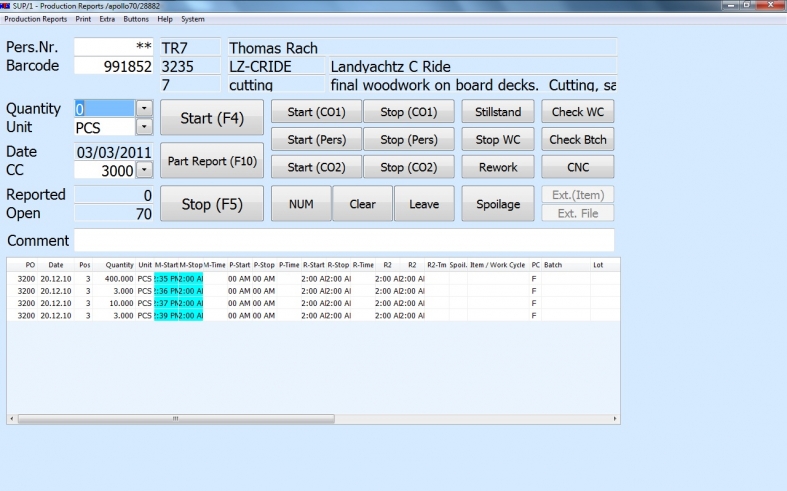

Apollo Production Planning / Scheduler Module

An end to end production management solution is a key component of success in industrial fabrication and manufacturing. Apollo Production delivers an extremely powerful suite of tools that allow organizations to bring together mission critical information and closely integrate the functions of all associated parties to quickly assess production needs against resource availability. This module takes it many steps further by calculating recommendations to purchasing based on material requirements using a just-in-time methodology to prevent unnecessary inventory costs as well as reporting in real time the status of all open work orders in order to provide important feedback to stakeholders.

Apollo Production communicates with staff involved at the shop level through several streamlined methods, which are fully customizable to include multi-lingual support on screen as well as printing multi-lingual work orders and providing easy to use scanning interfaces for reporting progress within work cycles.

Features

- Multi-level production orders

- Direct and automatic material demand calculation

- Multi-lingual production papers

- Work cycle reporting (via Scanner)

- Production cost

- Graphical machine overview and status

- Forward and backward calculation of machine utilization

- Interactive Gantt chart

- CNC program administration

- Flexible versions per item and production order

- Administration of external work cycles

- Evaluation of work in progress

- Direct access and overview from sales and customer orders down to the production order and shop-floor reports

- Automated checking of material availability and creation of re-order requirements

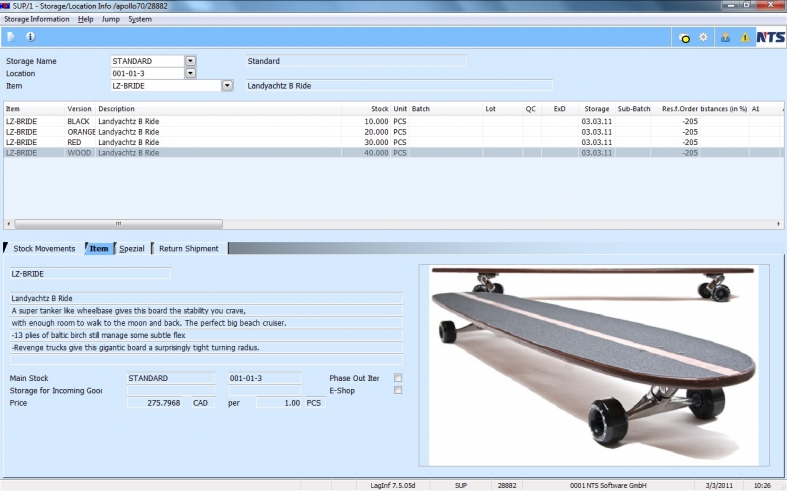

Apollo MRP Module

Material availability is vitally important within all manufacturing environments. However, organizations that are engaged in the fabrication of highly sophisticated products often find that most of today’s MRP systems aren’t able to deliver a corresponding level of sophistication. Apollo MRP is an extremely robust material requirements planning software solution in that it can track an unlimited number of items in multi-level nested bills of materials along with the human and machine resources needed to complete all work cycles. Additional layers of intelligence are available in the form of item expiry date controls, batch management through Apollo Batch Control, tracking of pharmaceutical ingredients as well as serial number generation and tracking.

Features

- Multi-level nested Bill of Materials

- Formulas for material demand calculation

- Cost calculation

- Conditional BOM-elements

- Forward and backward machine utilization and capacity calculation

- Capacity planning with shift planning

- Interactive Gantt chart

- Real-time online demand calculation

- Graphical representation of machine utilization

- BOM automatically generates material bookings

- Batch, lot and serial number control

- Unlimited number of storage locations

Apollo Batch Control / Serial Numbering Module

An ERP systems ability to provide the end user with visibility into the existing stock levels of a company in a multitude of ways is sometimes overlooked. Apollo’s Stock and Batch Control Module allows you to quickly ascertain existing stock levels as well as more detailed cross sections of existing assets within the total stock counts. They can include such detailed information as available stock within the total count, as well as availability mapped across a time axis considering incoming and outgoing materials. It is also possible to view a multitude of data related to a single item such as quantity produced in total, within a batch, locate the other items from the same batch, track items by serial number… all with a complete historical record that is unlimited.

Features

- Complete multi-level nested batch tracking

- Individual properties per batch (e.g. % of active pharmaceutical ingredients, calories, texture, color)

- Top-down or bottom-up tracking of materials

- Batches, lots and serial numbers

- Batch and lot labels with barcode

- Expiration date control

Apollo Purchasing Module

The core utility of the Apollo Purchasing Module is to provide purchasing agents with the most streamlined and automated tools available to assist in the management of materials demands from within to the relationships with suppliers. With full control over invoicing for all purchase recommendations the functionality built into this module allows for more complicated structures that are relevant to different purchasing scenarios such as blanket and call-off orders as well as complicated billing arrangements.

Features

- Material demand calculation

- Purchase orders

- Incoming goods

- Blanket orders and call-off orders

- Complete price history per item and supplier

- Unlimited number of suppliers per item

- Multi-currency

- Multi-language

- Supplier item numbers

- Supplier batch numbers

- Supplier delivery reminders

- Automated supplier ratings (ISO-900x conformity) based on quality, delivered quantity and timing

Apollo Quality Assurance Module

Apollo’s Quality Assurance Module eliminates the need for external QA systems and helps tighten the tolerances of your production line to standards that exceed expectations within our aerospace and pharmaceutical customers work environments.

Features

- Multi-level batch control

- QA flags

- Lot control

- Suitable for pharmaceutical companies (FDA)

- QA quarantine storage management

- Integrated QA work cycles

- Blocking of materials

Apollo Logistics Module

Shipping goods is much more than just wrapping them up and putting them on a truck. It’s about shipping them at the right time with the right papers to the right customers with the right carrier. It’s also about optimizing freight costs, keeping deadlines in sight and managing backlogs. On top of that, there’s the need to print the shipping papers in the right language, using the correct VAT as well as log everything in the booking system and manage all of your personnel that are associated with these steps.

Features

- NTS Apollo Shipping ~ Inbound & Outbound Interfaces

- Invoice generation

- Delivery notes

- Packing lists

- Delivery requirement list

- Barcode and scanning options for sending and receiving

- Automated returning of incoming merchandise (e.g. due to quality concerns or mismatching delivery papers vs. orders)

- Unlimited number of storage locations

Apollo Project Management Module

Producers of complex machinery or custom made products often have to deal with a variety of quotes and nested orders for the same customer. To connect all this information and make cross-connections visible to the end user this special module for project management has been added to the Apollo ERP Platform. Apollo Project Management allows you to see, in a tree view style dialog, all the connected data at a glance. Integrated drill-down functions allow you to go as deep as you want.

Features

- Project number attached to every action (order, quotation, invoice, production order, delivery note etc.)

- Graphical overview of the complete project

- Top to bottom drill-down into every project

- Production orders and work cycle reports

- Can also connect orders from different customers to one large project

Apollo Business Intelligence Module

It is well known at this point that evaluating large amounts of data visually allows for much faster interpretation of the data set as a whole. Visualizations give the end user a quick path to identifying key trends as well as critical outliers that needs attention. This is extremely valuable for staff within all facets of your organization, from sales to purchasing as well as production, but especially your management teams.

Due to the enormous amounts of data that can be stored over time about your organizations sales, purchasing, production, warehousing and logistics history, it is important for you to be able to drill down quickly and easily into it. Apollo Business Intelligence allows you to accomplish this with minimal effort.

Features

- Graphical statistics interfaces

- User-friendly dashboard

- Numeric and graphic key indicators (“traffic light warnings”)

- Variable views of all existing data

- Drill-down options for deeper insight

- Graphical extension to the liquidity planning tool

Apollo Electronic Data Interchange Modules (EDI)

Apollo ERP makes life even easier by making available the Apollo EDI Module with over 20 standards for electronic data interchange built right into your ERP system, eliminating the need to look at 3rd party solutions.

Electronic Data Interchange is critical to some businesses where large and often critical portion of data need to be regularily exchanged with key partners. By communicating electronically through the EDI module your ERP operates in real-time with your suppliers, vendors and customers should you wish it to.

Features

- Compliant with over 20 different EDI standards (VDA, EDIFACT etc.)

- Incoming orders

- Outgoing order responses

- Outgoing delivery notes

- Outgoing invoices

- Call-off orders

Apollo Service & Repair / Returned Merchandise Authorization Module

The Apollo Service Module enables your logistics staff to easily manage items that are being returned due to any number of possible reasons with a multitude of possible outcomes. The Return Merchandise Authorization (RMA) interface allows for the generation and management of individual RMA’s, as well as the management of the processes associated with each of the returned items. Whether the returned product is being repaired for return to the customer, repaired for return to stock, or simply replaced under warranty, the Apollo Service Module helps maintain control of the situation. The module also allows for the tracking of individual items, the batch it came from, and the entire history of the product.

Features

- Recurring service orders

- RMA-numbers (RMA = Return Merchandise Authorization)

- Serial number tracking

- Item history (by item number, serial ID and customer)

- Stock overview

- Repair-to-stock

- Repair-to-customer

- Material planning

- Invoicing